Teak Wood Trunk Epoxy Table DIY

Creating a custom epoxy resin table is a fantastic way to showcase both the beauty of wood and the artistic potential of resin. By combining a teak wood slab with a shimmering epoxy finish, you can craft a unique piece that serves as a stunning focal point in any space. The process involves carefully sanding the wood, routing canals to hold the resin, and then pouring epoxy to fill the voids and add a touch of sparkle. Whether you’re an experienced woodworker or a DIY enthusiast, this step-by-step guide will help you transform a simple teak slab into a one-of-a-kind masterpiece that perfectly blends natural elegance with a modern, artistic flair.

Materials & Tools You’ll Need:

- Teak wood slab

- Sanding equipment (orbital sander, sanding blocks, or hand sanders)

- Router (to cut canals)

- Epoxy resin (for pouring into canals and a clear topcoat)

- Glitter or shimmer powder (to mix into the clear epoxy)

- Epoxy mixing cups & sticks

- Plastic sheeting or drop cloth (to protect the workspace)

- Masking tape (for sealing the edges of the canals)

- Legs (for the base, whether pre-made or custom)

- Rubber gloves and safety gear (for protection when working with epoxy)

- Fine sandpaper (for finishing)

- Heat gun or torch (optional, for removing bubbles from epoxy)

Step-by-Step Process:

1. Prepare the Wood Slab

- Inspect the slab: Check the slab for any cracks, voids, or imperfections that may need attention. Since you’re planning to add epoxy, any natural cracks or holes can be filled with resin.

- Clean the surface: Wipe down the wood to remove dust and debris.

- Sand the surface: Start with a medium-grit sandpaper (around 80-120 grit) to level the surface and remove any old finishes. Finish off with finer grits (180-220) to smooth the surface for a better bond with the epoxy. Sand the edges too, as this will help ensure a clean edge once the epoxy is poured.

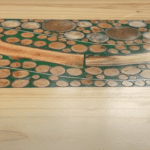

2. Route the Canals for Epoxy

- Mark the areas: Decide where you want the canals for the epoxy. These can be straight or curved, depending on your design.

- Router setup: Use your router with a suitable bit (like a straight bit or v-groove bit) to carve out the canals. Ensure that the depth of the cut is consistent to hold the resin properly.

- Protect edges: Use masking tape along the edges of the canals to prevent any resin from spilling over onto areas where you don’t want it.

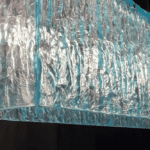

3. Pour the First Layer of Epoxy Resin

- Mix the epoxy: Follow the manufacturer’s instructions carefully for mixing the two parts of your epoxy resin (resin and hardener). Ensure it’s thoroughly mixed to avoid any uncured areas.

- Pour the epoxy: Pour the mixed resin into the canals. Be careful to fill them evenly and avoid overflow. You can use a stick to help guide the resin if needed.

- Let it cure: Allow the epoxy to cure fully. Depending on the type of resin and environmental conditions, this may take anywhere from 24 to 48 hours. Ensure it’s completely hard before moving on to the next step.

4. Apply the Sparkle Epoxy Coat

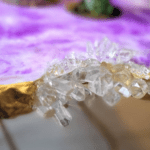

- Prepare your sparkle epoxy: Once the canal epoxy has cured, mix another batch of clear epoxy resin. Add glitter or shimmer powder to this batch. You can choose any color or type of shimmer for the effect you want.

- Pour the topcoat: Pour the mixed shimmer epoxy resin over the entire surface of the table. Make sure the resin spreads evenly across the surface, filling in any low spots and covering the wood entirely.

- Use a heat gun or torch: After pouring, use a heat gun or a propane torch to gently remove air bubbles that may rise to the surface.

- Let it cure: Allow this layer to cure fully. This can take several hours, depending on the type of resin used.

5. Sand and Finish the Surface

- Light sanding: Once the epoxy has cured, lightly sand the entire surface with fine-grit sandpaper (around 400 grit) to smooth out any imperfections and to remove any high spots or air bubbles.

- Polish the surface: After sanding, you can polish the surface for a high-gloss finish using a polishing compound. Alternatively, you can add a final clear coat if you want an extra layer of protection.

6. Attach the Legs

- Choose the legs: Select legs that match the style of your table. Pre-made legs (metal, wood, or hairpin legs) can be purchased, or you can make custom ones.

- Attach the legs: Position the legs evenly on the bottom of the slab. Use screws or bolts to secure them firmly, ensuring they are centered and provide adequate support for the table.

7. Final Touches

- Inspect the table: After everything is attached and the resin is fully cured, inspect the table for any final sanding or touch-ups that might be necessary.

- Clean the table: Wipe down the surface to remove dust or fingerprints, leaving the epoxy finish smooth and shiny.

Tips for Success:

- Temperature and humidity: Ensure you work in an environment where the temperature and humidity are controlled, as epoxy resin is sensitive to these factors.

- Safety: Always wear protective gear, such as gloves and a mask, when working with epoxy, as the fumes can be harmful.

- Level surface: Make sure the table is level when applying the resin, as an uneven surface can result in a lopsided or uneven finish.

- Don’t rush: Allow the resin to cure fully before sanding or adding additional layers. Rushing this step can result in soft or imperfect finishes.

Following these steps, you’ll end up with a stunning teak wood epoxy resin table with sparkling effects that are both functional and visually striking. Enjoy your custom creation!